J.RADIOANAL.NUCL.CHEM., LETTERS 153 (5) 345-355 (1991)

I.N. Beckman, I.M. Buntseva

Moscow State University, 199234 Moscow, USSR

The state of radon in crystalline polymers, polyethylene and polypropylene, has been studied by methods of macro- and microauto-radiography. Radon-222 was introduced into the samples by diffusion from the gas phase at various temperatures and time intervals. Effects on the state of radon of such factors as density and polymer crystallinity, extent of macromolecular chain branching, spherulitc radius, content of different admixtures, y-ray photon irradiation dose or irradiation with accelerated electrons, etc., were investigated. In pure polymers, radon was found to be in an atomically dispersed state. Radon forms thermally stable accumulations at the surface as well as in the bulk of the material due to admixtures, gas bubbles and crazes. The probable effect of radon's tendency to form accumulations on the kinetics of its diffusion in crystalline polymers is discussed.

Modern radiochemistry pays considerable attention to the investigation of the radionuclide state in solids. Unfortunately, radioactive gas-in-polymer systems are poorly studied. Furthermore, the diffusion of heavy gases (radon, for example) is always complicated by the strong tendency of such gases to form accumulations [1].

The present work is devoted to the utilization of macro- and microautoradiographic methods (ARG) in the study of radon local heterogeneous distribution in crystalline polymers like polyethylene and polypropylene. Main attention is focused on investigating the influence of radon-222 distribution on such factors as crystallinity and morphological peculiarities of the structure of crystalline polymeric materials, content of admixtures and gas bubbles in them, etc.

Technical and chemically pure (recrystallized 3 times) polyethylene of high density (PEHD) with crystallinity, fC , ranging from 50 to 60 % polyethylene of low density (PELD) with fk=40-50% and polypropylene (PP) with isotacticity more than 99% were used for investigation. Samples in the form of (1-2)x10-4 m thick films or 10x10x50x10-3 m blocks were prepared by compressing grains between cellophane padding in a forming press with controlled heating. The polymers were heated at a speed of 15 degrees per minute to the required temperature (130-135░C for PELD, 140-145░C for PEHD, and 210-220░C for PP), the pressure was elevated to 2-3 MPa, and samples were kept in these conditions for 1 h, then cooled at a rate of 6-10 degrees per minute without decreasing pressure. PP films with large spherulite structures were prepared by prolonged (8 h) thermal crystallization of the polymer in an inert atmosphere at 145░C.

Polymer sample analysis in polarized light revealed that in PELD, spherulites are of a diameter smaller than 5x10-6 m, in PEHD films, separate spherulites of (15-20)x10-6 m were encountered, while the structure of PP films was represented by (15-20)x10-6 m spherulites randomly distributed throughout the whole sample. Prolonged annealing of PP at 145 oC led to the formation of spherulites with a diameter less than 400x10-6 m.

Some PELD samples were subjected to radioactive thermal modification by irradiation to various g-radiation doses 60Co with radiation power of 5x103 Gy h-1 and accelerated to 1 MeV electrons with radiation power of 10 Gy h-1. The value of absorbed irradiation dose was determined by measuring the gel fractions of a reference sample and by IR spectra.

Radon was introduced into the polymeric materials by the following methods:

Usually samples were kept in contact with radon during three hours to reach radioactive equilibrium between radon and decay products. Autoradiography was used to investigate radon distribution on the surface and in longitudinal sections of the sample (i.e. in the bulk of the material). To enhance image contrast, some samples after diffusion annealing in radon atmosphere were heated in vacuum to different temperatures and for various time intervals. This led to radon extraction from mobile zones, and ARG registered only radon left in the polymer in the form of accumulations.

After diffusion experiments the samples were frozen in vapors of liquid nitrogen to prevent diffusion and were placed in contact with photographic plates covered with a thick-layered nuclear photoemulsion, specifically selected for the registration of alpha-radiation. Exposure was performed at -10oC in order to reduce radon loss and to improve the autoradiographic image.

Two methods of autoradiography were used, macro-ARG and micro-ARG:

Using macro-ARG, the autoradiogram was photometered on a scanning microphotometer and package of data was obtained which characterized the distribution of the darkening density on a chosen region of the autoradiogram. The results were analyzed by a computer. Special programs enabled to draw isolines of similar darkening density, to pass to concentration profiles (taking into consideration the decrease and dispersion of irradiation in the material), to draw histograms of gas concentration distribution through the surface and bulk of the sample, etc. [3,4]. Enhancement of contrast and exposure of "relief" details were conducted by 2-dimen-sional image differentiation with subsequent nose suppression.

Using the micro-ARG (i.e. track ARG), autoradiograms were investigated under a microscope. A special device enabled to measure the spatial orientation and length of a-tracks, thus providing the possibility of determining the coordinates of irradiation source deposition. During ARG analysis the distribution of track length, as well as topology maps of atomic radon distribution on the surface and in the material were drawn. A complex of programs permitted to automatically detect radon accumulations ("stars" on ARG), measure spatial coordinates of accumulation deposits (x,y,z), calculate parameters of the accumulations and to determine the number of radon atoms in an accumulation. The comparison of ARG and a photograph of the respective region of polymeric film in polarized light permitted to determine the connection between the location of accumulations and individual morphological formations in the polymeric structure.

|

|

|

|

|

|

|

|

|

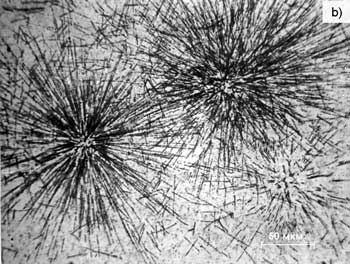

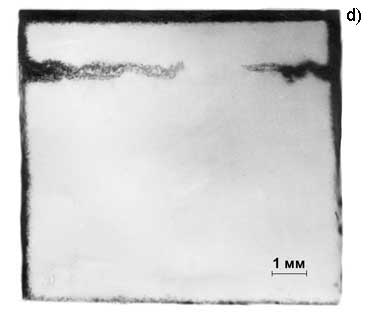

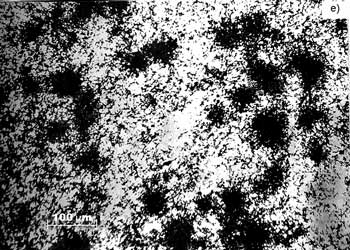

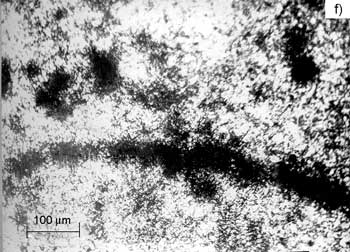

Fig. 1. Autoradiograms of radon distribution in polyethylene and polypropylene, a - Radon in pure triply recrystallized PEHD; b - Accumulations of radon on the surface of PELD technical films; c - Accumulations of radon in the bulk of technical PELD; d - Accumulations of radon in gas bubbles, which appear after irradiation of PELD blocks with high doses of electrons accelerated up to 1 MeV; e - Accumulations of radon in interspherulite space; f - Accumulation of radon at the border of a large spherulite

Analysis of the results shows that in the majority of cases (with an accuracy of the resolving ability of ARG, i.e. several microns) radon is uniformly distributed in the polymeric material (Fig. 1a). However, in some cases inert gas distribution figures displayed a non-uniform character. Thus, ARG of technical polyethylene samples revealed a relatively large number of accumulations (Fig. 1b, c), meaning that this material had a substantial amount of nuclei with an abnormally high adsorption capacity. Apparently, these adsorption-active nuclei are related to the presence of admixture residues in technical PELD. Three-fold recrystallization of PELD in toluene leads to the refinement of the polymer, and as a result, to the removal of accumulations. The total amount of adsorbed radon is reduced approximately 10-fold.

Sample irradiation with ionizing radiation to doses of 1 MGy in atmospheric air leads to a ca. 20-fold increase in the amount of adsorbed radon compared with nonirradiated PELD. Nonradon accumulations can also be detected. At higher doses, ARG of the sample surface fixes the development of accumulations topologically related to microbubbles made by gases, products of polyethylene radiolysis. Longitudinal sections of samples irradiated with doses of 10 MGy by electrons accelerated up to energies of 1 MeV demonstrated the development of a substantial number of radioactive defects quite active with regard to trapping radon. As a result, in ARG accumulations are grouped into compact lines of darkening. Closed separate micropores are located at a distance of 0.5-0.8 Re from the entrance of the sample surface (Re, accelerated electron path in the polymer). At depths of 1@0.8-0.9 Re separate defects combine into a unified system of pores, thus facilitating permeation of radon into the polymer. At even greater irradiation doses a highly defective layer (Fig. 1d) is formed at l=0.2-0.3 Re . The layer is characterized by a large diffusion coefficient (the rate of radon diffusion is comparable with the rate of its migration in the gas phase).

As a rule, diffusing radon does not decorate morphological formations in pure crystalline polymers such as PE and PP. However, in PP with large spherulite structures (diameter of spherulites reaches 2x10-4 m) single accumulations in the form of "stars", made by alpha-particle tracks are detected on ARG. Comparison of ARG with photographs of PP film in polarized light revealed that accumulations are distributed along the borders of spherulites and in regions between them (Fig. 1e). Inside the spherulite, radon is in an atomically dispersed state, which is registered in the form of chaotically located tracks. At increased spherulite dimensions (up to 5x10-4 m and more in diameter) radon accumulates in the form of an even layer surrounding the spherulite (Fig. 1f). Such an accumulation is registered on ARG as a layer of "stars". The diffusion properties of this layer are similar in their diffusion parameters to micropores, however, no through flow around spherulites can be detected, and PP films retain their barrier characteristics.

Thus, as a rule in crystalline polymers, radon is in an atomically dispersed state. However, due to macro-defects (gas bubbles, microcracks, etc.) or admixtures, the autoradiogram registers the presence of radon accumulations. These are thermally stable and retained during the extraction of radon in an atomically dispersed state.

The occurrence of radon accumulations in polymeric materials can significantly alter the diffusion kinetics of radon. Thus on the release curve of thermostimulated radon during linear heating, two peaks of gas release may appear: one connected with the release of atomically dispersed radon, and the other, with the release of radon condensed on microdefects and admixtures (the latter peak appears at temperatures higher than the polymer melting temperature). The same effects should be taken into account when forecasting diffusion properties of gas-separating membranes used for the preparation and purification of radon, such as polymer wrapping material for compounds of radium-radon, barrier films, which block the emission of radon from building materials, etc.

On the other hand, in polymers the use of radon for the decoration of structural formations enables to detect point defects and their accumulations, to decorate spherulite borders, inclusions of admixture phases, micropores, etc. The quantitative processing of radio-nuclide distribution pictures in the bulk of the sample permits to determine spatial location of defects, the transport and diffusion properties of various types of defects.

It should be noted that the use of diffusion gas probes (in the present case, radon) has several peculiarities compared with other methods of decorating structural formations in polymers. Nonvolatile decorating agents (for example, radium [5]) are introduced into solids during their thermal processing. After crystallization, the decorating agent is displaced from the crystallites (and to some extent from spherulitos) and concentrated on their surface, thus visualizing borders. On the contrary, diffusion probes are used for investigating stable structures. Therefore, the use of radon permits to carry out nondestructive defectoscopy of products made from polymeric materials.